Service Line:+86-022-82164980

Address:FL-4, Building A5, International Enterprise Community, Tianjin, China

Email:[email protected]

(1)(1).png) |

KMD Bioscience has a mature antibody production platform with advanced and improved antibody engineering technology. You can enjoy comprehensive polyclonal antibody production services, including peptide or protein antigen synthesis, animal immunization, antibody purification, and QC control tests. Polyclonal antibodies can also be raised against customer-supplied antigens. Our scientific team has been practicing polyclonal antibody development for years, with upgraded recombinant antibody production technology, KMD Bioscience can develop high-quality polyclonal antibodies and guarantee positive binding to antigen in ELISA assay. |

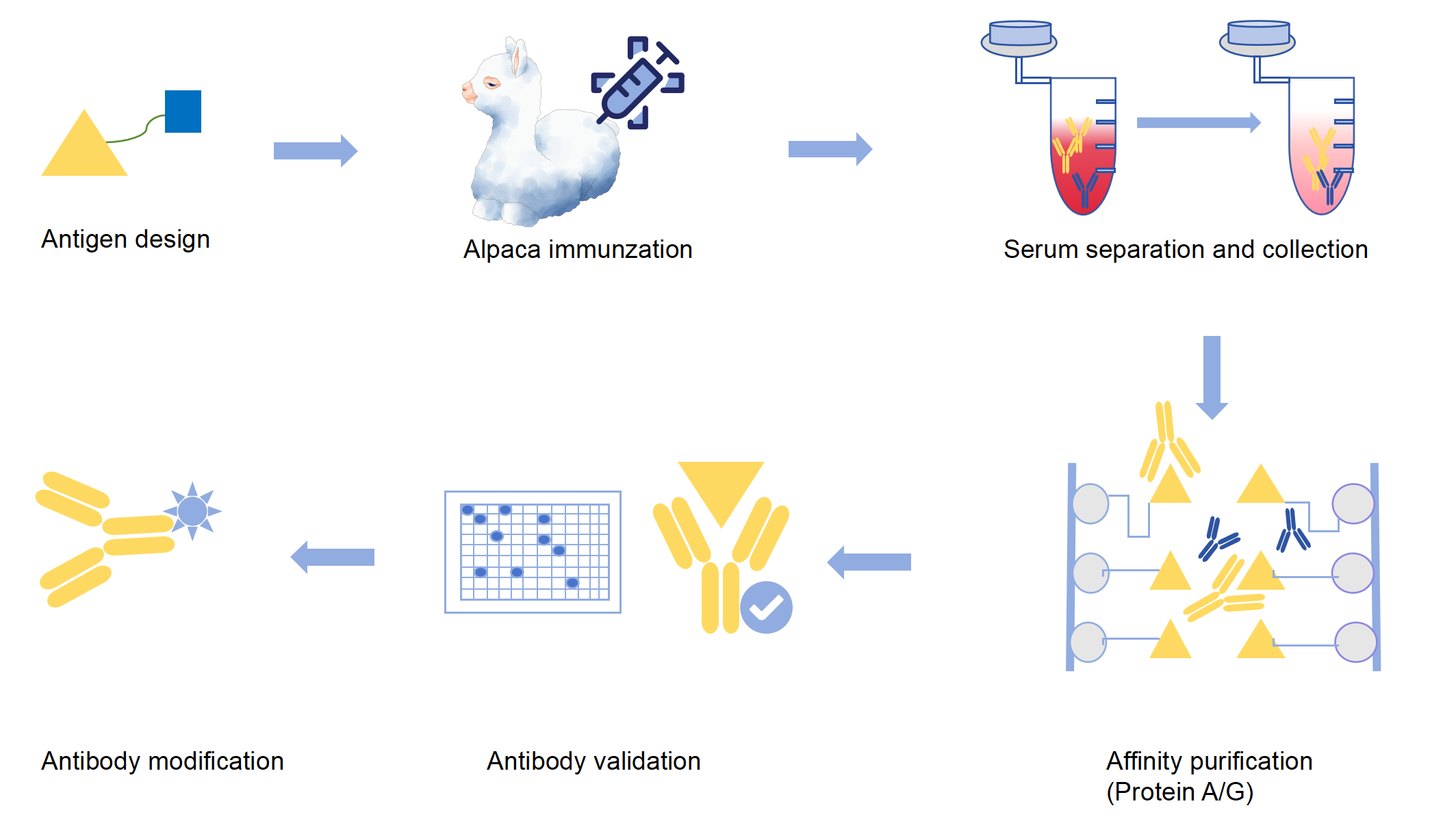

Alpaca antibodies can withstand elevated temperatures and a wide pH range, which makes them of great interest for basic research and therapeutic applications. Custom alpaca polyclonal antibody production services are available to serve your specific research goals. KMD Bioscience can also provide antigen design, peptide synthesis, gene expression, recombinant antibody expression, antibody purification, de novo antibody sequencing, identification, and antibody labeling services with our independent and advanced recombinant antibody expression platform.

Alpaca Polyclonal Antibody Production Background

Unlike human Igs-consists of two heavy chains and two light chains, llamas, as all members of the camelid family, produce antibodies with an original scaffold only made of heavy chains (IgG2 and IgG3), called heavy Chain Antibody(hcAb), thus promoting binding to structural motifs unreachable before in protein targets, such as viral and enzymatic proteins. The hcAb contains a single variable domain (VHH) and two constant domains (CH2 and CH3). According to the report, cloned and isolated VHHs possess unique properties that enable them to excel in conventional therapeutic antibodies and their smaller antigen-binding fragments in cancer targeting and therapy. VHHs express low immunogenicity, are highly robust and easy to manufacture, and have the ability to recognize hidden or uncommon epitopes. The advantages of hcAb are significant: stability maintained even at 60°C, high tolerance to extremes in pH and temperature, and well-expressed in microorganisms such as bacteria and yeast.

Alpaca Polyclonal Antibody Production Service Process

Alpaca Polyclonal Antibody Production Service Workflow

|

|

Protein |

Peptide |

|

Antigen Preparation |

* 3-5mg * Molecular Weight>20 kDa * Concentration>0.5mg/ml * Purity>90% |

* ~10mg * >12 amino acid * Purity>85% |

|

Peptide Conjugation |

|

* KLH, BSA, OVA, Hydralink |

|

Immunization and Sera Collection |

* Alpaca Immunization and boosts of 1 alpaca/camel (~120 days), and ELISA screening of the polyclonal sera |

|

|

Antibody Purification |

* Protein-A/G purification, ion exchange resin, antigen affinity chromatography, and density gradient centrifugation |

|

|

Antibody Modification (Optional) |

* HRP, AP, biotinylation * FITC, FAM conjugation * GST, His tag * Magnetic beads, Quantum dots |

|

Alpaca Polyclonal Antibody Production Service Highlights

--Rich experience in polyclonal antibody development.

--High affinity and specificity.

--High ELISA titer: Guaranteed pAb ELISA titer -107.

--Large-scale recombinant antibody production capability (all size runs available).

--Strict quality assurance: follow cGMP management rules.

--Ideal source of therapeutic antibody.

--An affordable alternative to monoclonal antibody production.

--One-stop downstream services, including antigen production, recombinant antibody expression, De novo antibody sequencing, antibody purification, ELISA kit development, etc.

How to Order?

If you have any questions regarding our services or products, please feel free to contact us by E-mail: [email protected] or Tel: +86-400-621-6806;